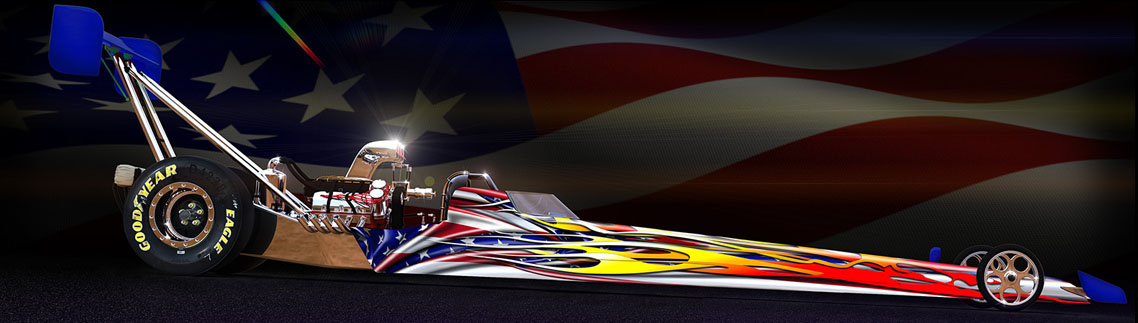

This is where to place your order for Sr. Dragster Wraps

The one thing that's just as thrilling as the thunder of an asphalt assaulting dragster, is the look that goes with it!

Please use the links below to double check your order by title before adding to cart.

Find some useful tips by clicking through the tabs in the column.

This site contains large and X-Large images so that you can dive into the details. Best viewed (and appreciated) on a large screen.

Excellent choice, and here are a few essentials so I can get started on customizing your new dragster wrap:

As there are a number of different dragster body styles and types:

1) Indicate the 'title' of the design you have selected and if it is being applied onto a solid fiberglass unit, or segmented aluminum panels.

2) E-mail me with profile and isometric image(s) of your dragster so that I can see the body style you are installing upon. Also include a reference of the nose cone.

3) In return, I'll compare what you have sent to the templates I already have in stock. You will be contacted if more information is required.

4) Turnover for proofing takes about 48 hrs,

and from time of processing to shipping is generally at least three days. You can figure seven day from start to being mail ready. Faster service can be arranged at a premium.

Once the custom design has been remastered to fit your model, a final proof will be provided back to you before processing starts.

A nominal fee is required for this service and is non-refundable.

The basic setup charge starts at $149.00

*Always start with a clean contaminant and dirt free surface.

If you can glide your finger across the surface and hear it squeak, you'll know that your surface is prepped well. And doing so will insure positive results when installing the panels onto the body components. It will also offer you with years of trouble free enjoyment as the 3M adhesives will bond better to the surface.

All said, always start by hosing dirt and sand off the surface, then follow up by washing down those surfaces with dish soap and clean water.

After it has dried, wipe everything down with rubbing alcohol just before you plan on doing the install. This will ensure that contaminants such as finger grease have been removed.

*Do NOT use a Chamois as it contains fish oils. Dry, lint free cloth will work fine.

Some industrial automotive products work even better than rubbing alcohol, however be sure to always test on an unseen area first, in the event of incompatibility. Always ask your supplier for details.

NEVER use Acetone or Lacquer thinner unless the surface you are working on can take such aggressive cleaners. Avoid them when working on fiberglass, gel-coat and some plastic surfaces.

If you have removed other decals and there is adhesive left behind, you may apply a generous amount of good old fashioned Paint Thinner or Mineral Spirits onto a soft cloth and hold it on the sticky area for about 5 seconds before wiping in a swirl pattern. You'll want to proceed with this circular motion until all has been carefully removed. Keep in mind that those products mentioned are Petroleum based, and will leave a slight oily residue behind that will in fact prevent good adhesion. So wipe down that area a couple more times with clean cloths and rubbing alcohol.

'Squeaky clean'

If it squeaks, you're good to go!

Dirt, grease and wax free!

*Whenever handling the adhesive side of the panel, keep fingers at least a couple inches in from the finished edges, as that area will be vital in maintaining a solid seal.

-----

'Working environment'

*Keep the workspace clean, particularly the floor.

You'll want to work in an environment with good lighting and in an ambient temperature in the 70's or higher. A heated shop or garage is perfect and away from windy openings as this may hamper your control over the media during installation.

Warm panels plus warm graphics make for an easier install. However too much heat will cause the media to become softer. Be careful not to overstretch the print if it needs to line up to other panels.

Quartz lighting, (like work lamps), can also assist in maintaining temperature in close proximity of the panels and the vinyl. This will also promote the adhesion.

In contrast, if it's too cold, you won't have the same success as the vinyl will be stiff and 'snappy'. As example, if you can peel back a section of the vinyl and it is quiet and comes off smoothly, then the temperature is reasonable. However the opposite applies, and if you hear a snappy sound and the vinyl is stiffer, it is too cold and you should pause to warm up the environment before continuing.

If your are not applying 'wrap' media specifically, the graphics should then be applied by 'wet' application.

The opposite holds true for 'wrap' and is always applied dry so that it stays in place while you work it over the contours.

If you have questions, you can always call the studio for technical support before you start.

More about 'wrap'

'Wrap' media, is thinner than most others by design, and can only work for smooth surfaces.

If doing a wrap installation in blazing summer heat on a smooth surface, it might make it difficult to move the graphics around and have control as it may be too 'soft'. If this is your only option, you may need to apply 'wet' as it will buy you time. On the other hand, if you have experience with 'wrap' media, you might find it advantageous and beneficial for all that heat, particularly if wrapping an organic shaped surface that has very strong curves.

Overall, wrap media is more expensive, yet one I personally would prefer to be working with over all others.

If you are inexperienced, please hire an installer as it may be better than taking risks and having to replace a panel.

Most commercial sign shops should have a staff member on hand who is well experienced with how this high performance media can be managed and manipulated into and over any shape.

They should be willing to quote a cost on the project.

And when hiring-out, I strongly advise in getting at least two estimates before proceeding.

Care after your new graphics are installed is no different than that which you would give a new car.

A soapy bath whenever required, and coat of wax will keep it looking glossy and new for many years.

I have used Mothers Carnauba for years, and highly recommend it.

The wonderful benefit of using vinyl graphics instead of having expensive custom paint applied, is that if ever you have a ding or scratch to fix, even a major panel to replace, it can be done in a fraction of time.

Not to mention that it will be just a few dollars, rather than hundreds spent in a paint booth. Small areas can be patched over practically unnoticed, thanks to the exquisite engineering of the 3M brand media we use.